Other Waterproofing Services

Resin Injection

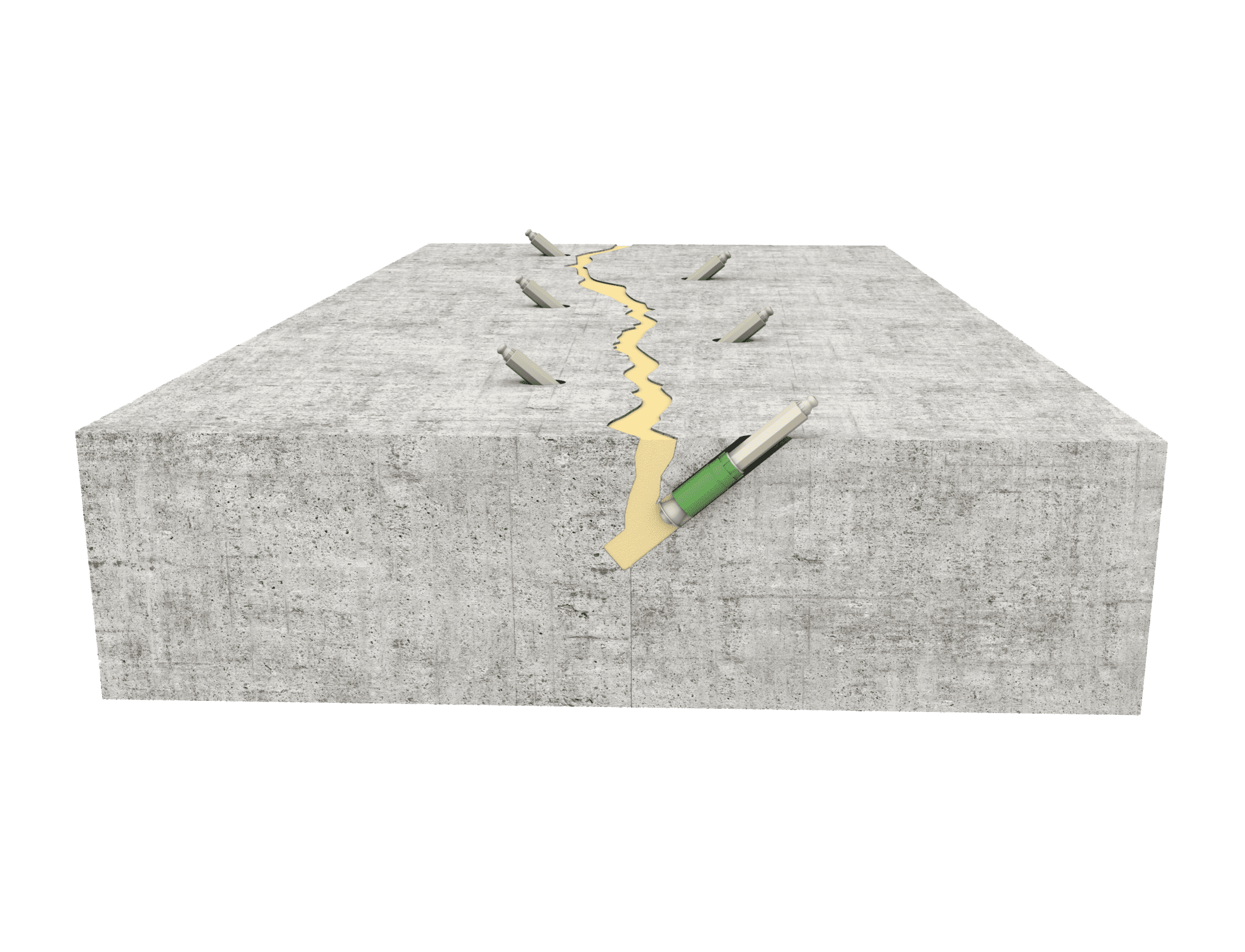

Where water penetrates through existing cracks within concrete, brick or blockwork substrates in below-ground structures, these can be sealed and made watertight through injecting reaction-curing materials.

Continuous leakage through substrate cracks often causes consequential damage such as reinforcement corrosion and over time it can lead to the structure filling up with groundwater culminating in flooding and further damage to the structure.

‘Static’ cracks (ie cracks that don’t open / close under structural load) can be sealed using a rigid reaction-curing (usually epoxy) resin. Conversely, ‘dynamic’ cracks (which DO open / close under load) need to be filled with a permanently elastic material such as a polyurethane resin.

Image Courtesy of Delta Membranes

Injectable Water Bars

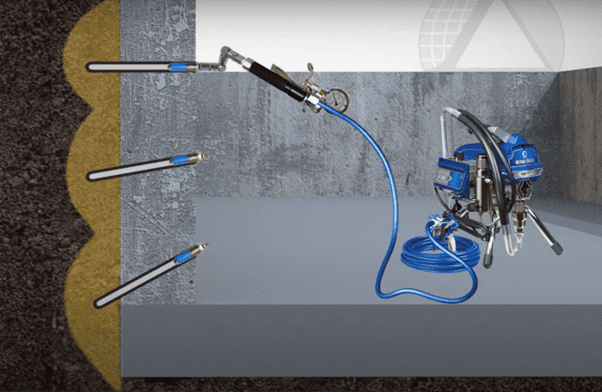

Injectable water bars are increasingly popular as standard water bars are prone to early or even immediate failure due to poor installation as part of the concrete construction joint process.

An injectable water bar is commonly used as a secondary / back-up water bar comprising a solid core PVC injection hose with a series of neoprene ‘valves’ that allow resin to be injected via the hose and in to the void that is needing to be filled to stop water ingress.

Once initially injected with resin to fill voids, if flushed out properly after initial injection, injectable water bars can be re-injected in future should leakage occur. Subsequent or secondary leakage can occur as a result of a change of ground conditions for example ie the local water table rises or a new building is constructed next to the existing etc.

Movement Joints

Movement joints are required where there is a void or gap between two or more separate structures. If left unfilled, these gaps or voids will allow water ingress hence why a barrier has to be created to prevent that ingress. Because the structures are separate and not joined together, the barrier material of the movement joint itself has to be watertight.

The joint is made watertight by adhering a continuous jointing material to the opposing faces of the different structures and usually surface-mounted . More often than not, they have to surface-mounted – known as ‘overbanding’. – either on the outside OR the inside of the structure. Importantly, the joint material must be non-biodegradable ie it DOESN’T ‘rot’ as wells as being capable of withstanding considerable water pressure so as to not fail in-service.

Joint-face adhering materials (ie materials that are inserted into and adhered to INTERNAL opposing faces of the joint itself) invariably do not work as they are unable to withstand the water pressure that builds up. These include gun-applied sealants that can be pushed out by water pressure.

Void Filling

Void filling is frequently required as part of the crack injection / resin injection process. If there is a void behind the crack within a below-ground structure that needs to be made watertight, the void will need to be filled prior to crack injection & sealing. If the void is un-filled, the resin that is being injected in to the crack simply seeps in to the void behind it and the cracks are not filled. As a consequence, a considerable volume of resin can end up being used simply partly filling the void rather than sealing the cracks; it also becomes VERY expensive!

Voids behind structures – be they concrete, brick or block – can be filled with (typically) an expanding, polyurethane-based injection resin. It works on the same principle as expanding foam although the expansion in this case generally happens by the resin coming in to contact with water.

Podium Waterproofing

A podium is usually a reinforced concrete deck sitting over another below-ground structure; it’s effectively the lid of the box that’s in the ground. Depending what sits underneath the podium dictates what waterproofing techniques are required. A podium level typically sits over something like a basement car park however it could be retail premises, leisure facilities or a storage facility.

Podium waterproofing historically has used overlapped sheet membranes or mastic asphalt. The limiting factor with overlapped membrane waterproofing is that it has many seams that can leak allowing water ingress. Mastic asphalt degrades over time becoming more brittle and susceptible to cracking. Importantly also, asphalt is a ‘monolithic’ layer that is NOT bonded to the parent substrate. When it leaks therefore (as a result of cracking or damage from excavation), water flows UNDER that asphalt and in to the structure below.

Using either hot or cold liquid-applied podium waterproofing membranes are SEAMLESS applications AND they are fully bonded to the parent substrate and are commonly much more successful in keeping podium levels watertight.

Polyurea Membranes (Hand & Spray-applied)

A key advantage of the spray application of waterproofing membranes is speed of application, particularly where there is a large area to be covered. Polyurea-based materials are known to have excellent resistance to water, chemicals, abrasion and impact. The nature of the material is also highly elastic so it can resist a lot of movement and elongation without tearing.

Spray applications are also 100% seamless which gives the waterproofing layer the highest chance of being waterproof compared with conventional sheet membranes that overlap.

Hand-application of polyurea is usually where smaller or difficult to access areas require waterproofing with materials being applied with a trowel, roller or even brush-applied.

Pre & Post-Applied Sheet Membranes

Sheet membrane waterproofing systems – incorporating a gas barrier (radon or methane) – are applied predominantly at the NEW construction stage of a below-ground structure. These are typically pre-applied to the EXTERIOR face(s) of the structure such as retaining walls or onto a sand-blinded sub-base before casting the ground slab. They can also be applied on to the formwork prior to the concrete structure’s placement.

Pre-application refers to where membranes are installed PRIOR TO concrete placement, as outlined above. ‘Post-application’ is for when a ‘box in the ground’ structure is constructed first (typically an excavated site) followed by the application of the membrane(s) prior to back-filling of the excavated ground.